Different Types of Roofing

Your roof protects you, so you should protect it. Prevent the issues that can cost thousands of dollars, intolerable working conditions, and an uncomfortable building. Roofing systems such as built-up roofing, elastomeric, metal roofs, weathered single-ply membranes, and mineral cap sheets, have many problems. From chalking, cracking, sagging, leaking (#1 problem), splitting, the list goes on…

All these issues can create a perfect storm for your working conditions or your tenants. When a roof starts to sag, the water from the rain or snowmelt will pool in one spot, eventually wearing down the roofing material, and penetrating the surface and next thing you know that water is on your floor. When a roof has cracks in the tar or seams and holes from fasteners, it means air can escape through your roof, forcing your HVAC system to run twice as hard, costing you dumpsters full of money.

So why do we think our roofing solution is the right one for you? We’ll come right back to that question but first, let’s go over the other roofing solutions out there.

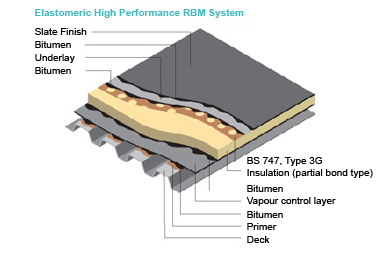

Built-up Roofing

Commonly referred to as “Tar and Gravel” roofs, built-up roofs, or BUR, are made up of alternating layers of reinforcing fabrics and bitumen. This bitumen can be made up of many different components. Asphalt, coal tar, and cold-applied adhesives are the most common. The BUR is applied in layers creating a “membrane”.

So why doesn’t this work?

- BUR roofing takes a long time to install because of the number of materials it uses.

- Hazardous fumes are often emitted during installation.

- High Installation costs.

- It’s susceptible to wind and moisture damage.

- It’s extremely heavy and requires roof joists to strengthen the structure.

- Find the source of the leak is hard and may require completely dismantling the roof.

- It’s not flexible in cold temperatures.

Elastomeric

Elastomeric coatings for roofs are more effective and affordable. They also come in 4 different coatings, each having their own pros and cons. These include; Butyl, Acrylic, Polyurethane, and Silicon. Each one of these coating is sprayed or rolled on and, once applied, provide excellent mildew and UV light protection due to its reflexive material. But, like many other roofing materials, it has its downsides.

- Poor performance in “Ponding”, where water pools on the top of the building causing leaks.

- Potential to lose mil thickness. This lack of thickness can allow moisture to penetrate the coating and seep onto the roof below.

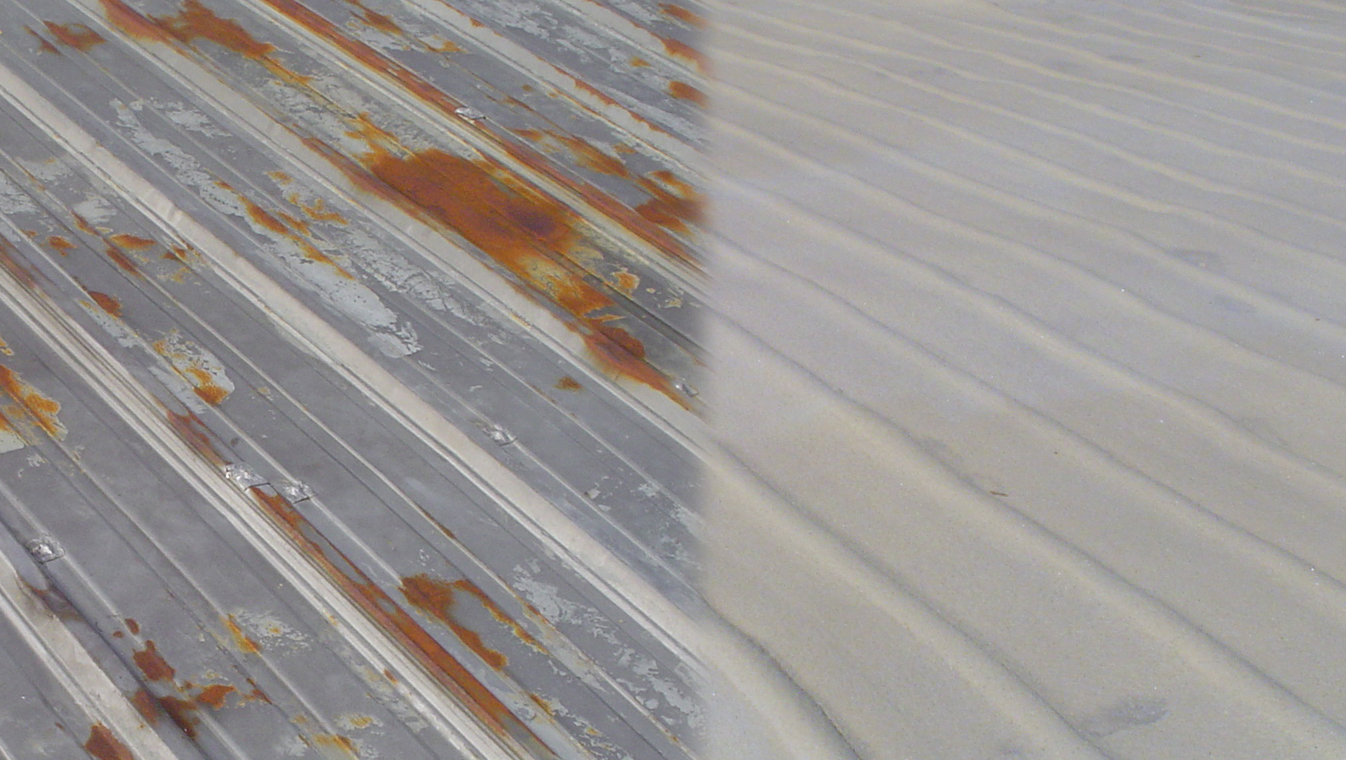

Metal Roofs

I know what you are thinking, “If all this asphalt and acrylic coatings have these downsides, why not just slap a big piece of metal on that roof and call it a day?” Well, kind reader, let’s go more in depth. Metal roofs do come with their own benefits. They can last upwards of 50 years and are incredibly durable, they will not corrode or crack and are fairly impact resistant. Metal roofing is pretty energy efficient and environmentally friendly, being composed of mainly recycled material. But, they have their downsides as well.

- Metal roofs can cost two or three times more than other roofing materials.

- They are incredibly noisy. So, if you enjoy that neighbor kids garage rock band, prepare to hear that all the time.

- Constant expansion and contraction may cause the panels to loosen.

- Accumulating water on poor quality metal can cause serious damage including rust and holes.

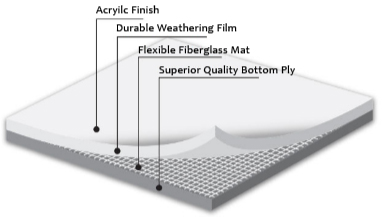

Weathered Single-ply membranes

Single ply roofing systems have a waterproofing layer that is laid over the original roof to provide a barrier to the elements. They are easy to install and have a lower inherent risk compared to more complex systems. These membranes are long lasting, cost effective, and environmentally friendly. But remember, this is just a single layer of protection. Let’s look at the cons.

- Flashing is a general concern.

- They are susceptible to low temperatures.

- Susceptible to punctures at a microscopic level that will lead to leaking.

- They tend to shrink and crack.

- If they are installed on polystyrene or asphalt, the plasticizers may leak out and cause more cracking.

Our Promise To You

You are probably asking yourself, “If there are all these downsides, which one do I pick?”. Thankfully, we at Energy Shield have the answers. We have been forerunners in the roofing industry for 40 years, we know what we are doing and we are proud of our work and our unique spray foam and silicon roof coatings. We offer 100% weather protection, 100% leak protection and a 50% reduction in your annual energy costs. Those are numbers anyone can get behind. Our spray foam and silicon coatings fill every little crack and seam, reduces UV rays due to its light color and keeps that nice air conditioned air inside, not leaking out. We worked this system out so well we don’t even have to tear off that old dingy roof, we can just spray it right over the old roof, saving you upwards of $20,000. Yeah, you read that number right. We know how stressful a leaking roof in poor condition can be. That’s why we promise you the only thing dripping at 9am is your coffee pot.

Recent Comments